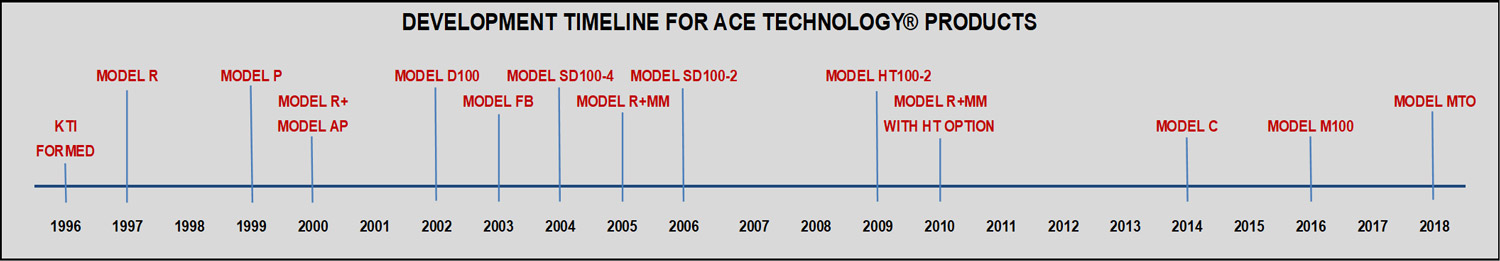

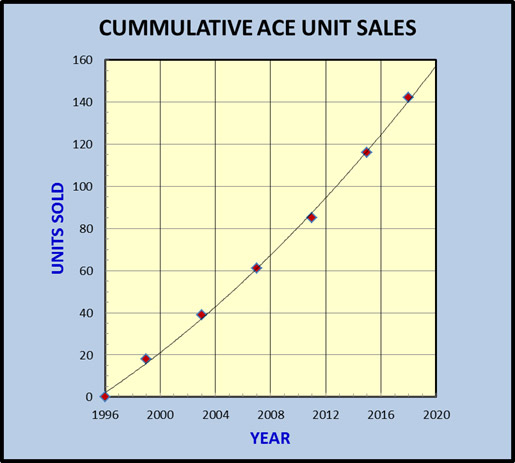

Company Scope and History: 1996-2020

From 1996-2020, Kayser Technology, Inc. provided laboratory-scale pilot plant equipment used to improve commercial petroleum and chemical operations throughout the world.

- TECHNICAL BASIS: Kayser Technology, Inc. invented the ACE reactor design (U.S. Pat. No. 6,069,012) which effectively replaced all prior small scale reactor designs for fluidized bed reactions on spray dried catalysts. Products that incorporate the salient features of this reactor are covered under the trademark name "ACE Technology®" (Advanced Cracking Evaluation Technology).

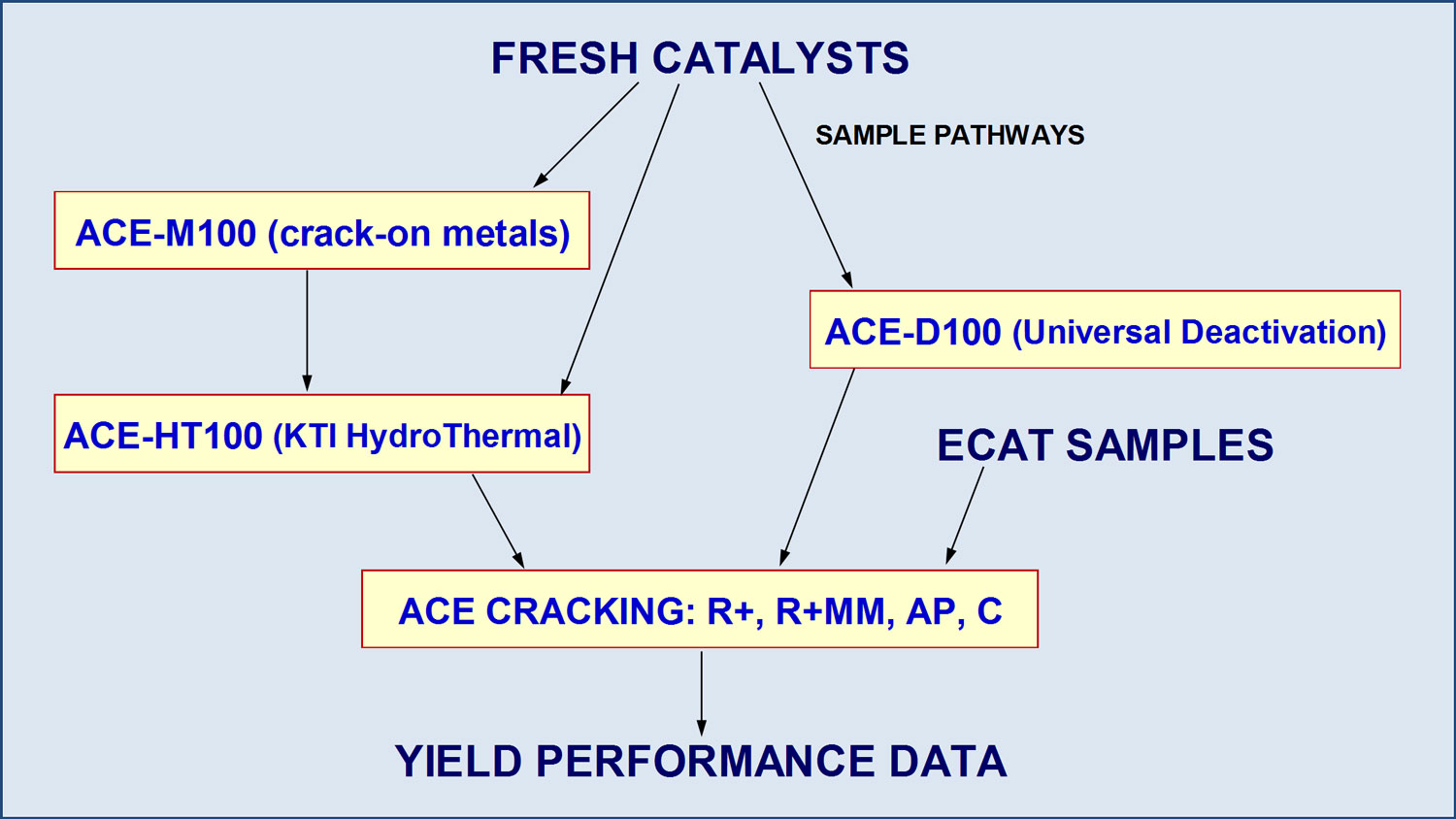

- SCOPE: Kayser Technology Inc. (KTI) operates primarily in the area of Fluid Catalytic Cracking (FCC) which is the main oil refining process for producing transportation fuels and petrochemical feedstocks. Laboratory-scale equipment from KTI is integral to steering commercial operations for improved performance and yields. Where applicable, KTI has used novel reactor technology for reactions different than FCC.

Commercialization of ACE Products

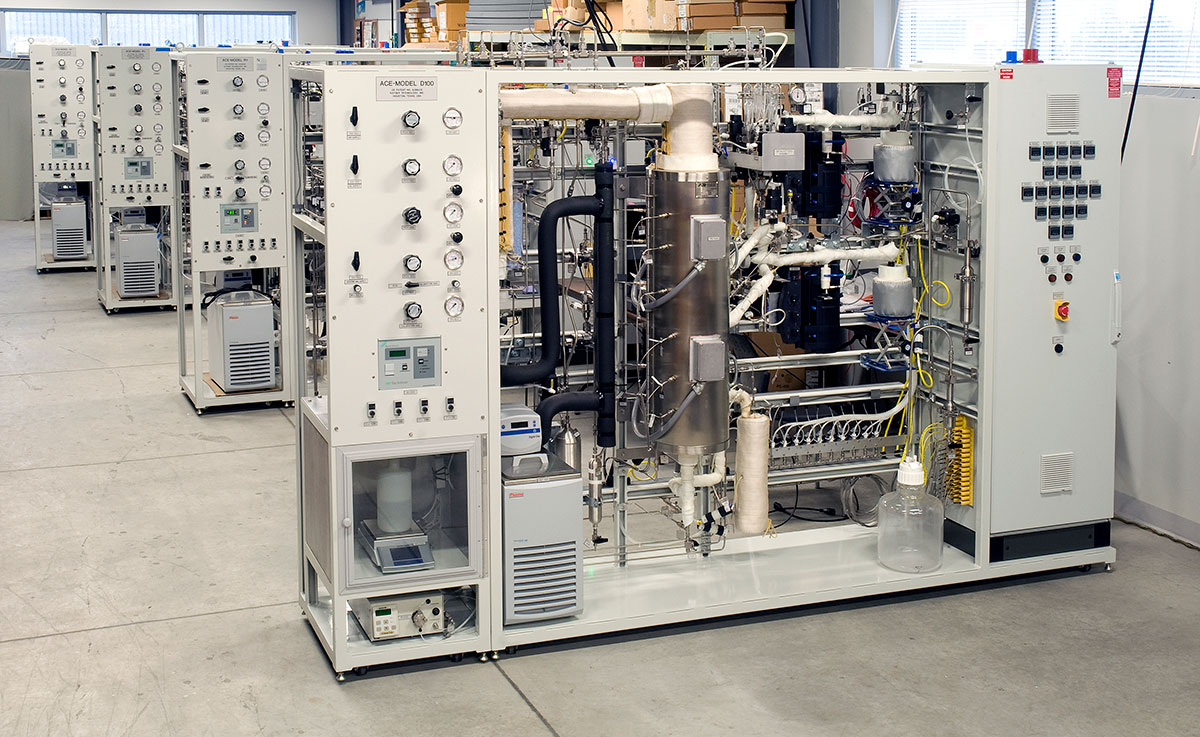

ACE Units in the Quality Control and Testing Area in 2009.

The Market for Kayser Products

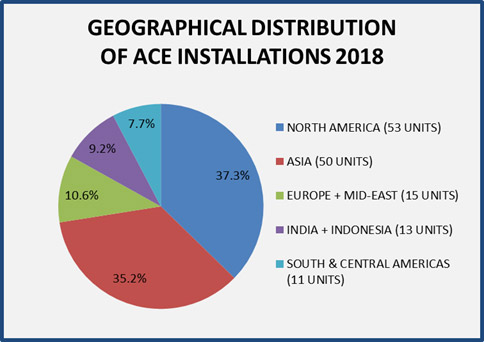

An International Business

ACE Technology® Products are used by petroleum refiners, petrochemical plants, catalyst producers, research centers and institutes, and process design and engineering companies.

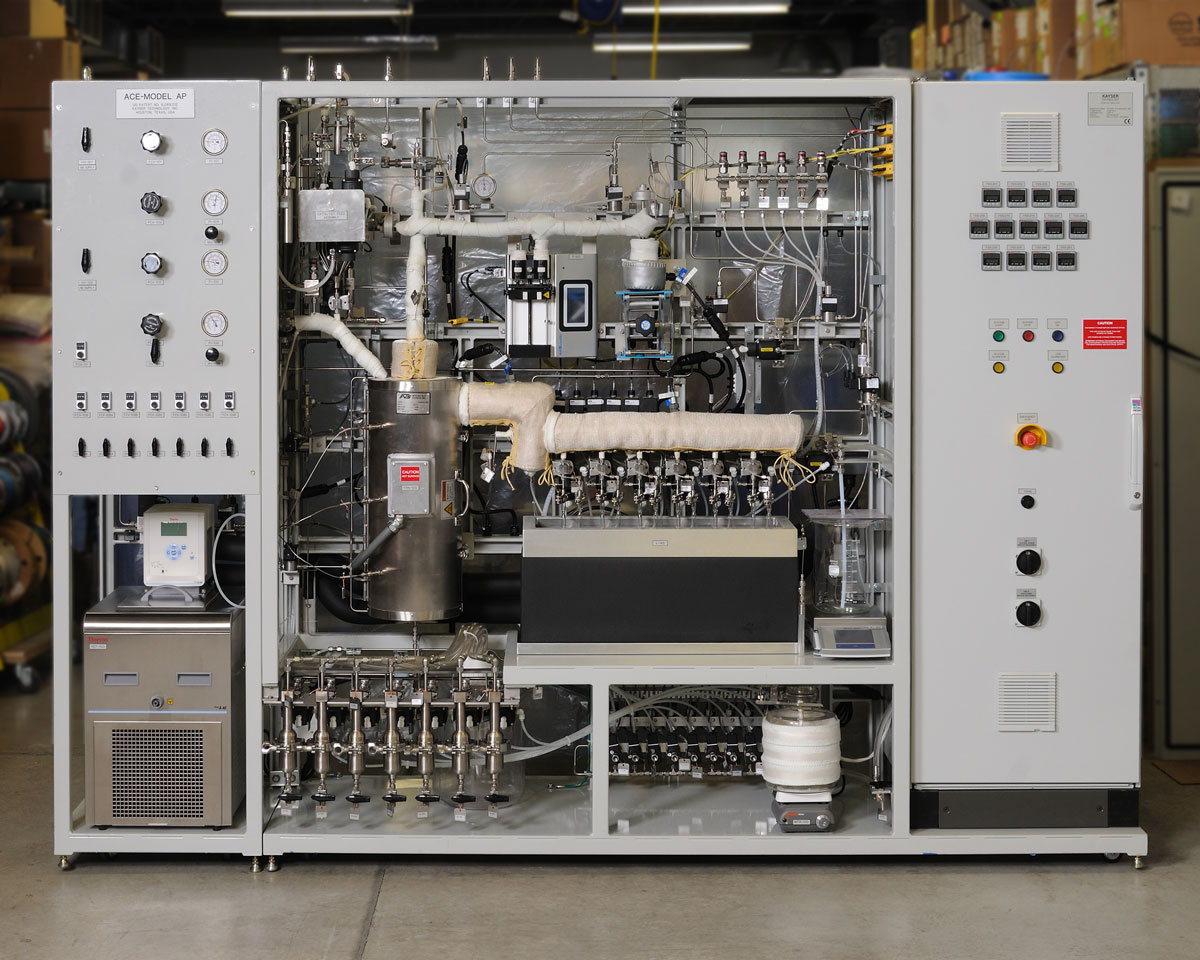

ACE-MODEL AP Unit (Automated Production): The activity and performance of ECAT samples are monitored worldwide predominantly by this technology (pictured below).